There are many factors that affect the market price of pure water equipment, mainly composed of equipment specifications (water production), equipment brands, equipment materials, equipment processes, market factors, and other aspects. The basic cost of the equipment is determined by its specifications, materials, technology, and brand, which are relatively stable. However, market factors are relatively complex and volatile. This article starts with the cost of equipment, and finally summarizes it based on personal market awareness.

The basic cost of pure water equipment mainly includes the following aspects:

Equipment specifications: Simply understood as process requirements+water production, the prerequisite for equipment production.

Equipment material: The water tank, pipeline, membrane shell and other parts in the equipment are greatly affected by the material selection. PE water tank vs. stainless steel (sterile) water tank, UPVC pipeline vs. stainless steel (sanitary) pipeline, fiberglass membrane shell vs. stainless steel membrane shell, etc

The material variables have the greatest impact on water tanks and pipelines. The regular configuration is PE+UPVC, the medium to high configuration is stainless steel pipeline+stainless steel (embossed) water tank, and the high configuration is sanitary grade stainless steel pipeline+stainless steel sterile water tank. Compared to the latter two, conventional configuration of water tanks and pipelines accounts for a lower proportion of costs, while high-end configuration has a higher proportion of costs, especially when the brand variable selection is conventional configuration, the proportion can even reach more than half.

Equipment brand: The equipment brand here refers to the manufacturer's brand of the equipment accessories (the same below), rather than the brand of the comprehensive equipment manufacturer. And equipment brands are also divided into core (equipment) brands and accessory (equipment) brands. The core brands mainly include pumps, RO membranes, EDI devices, polishing resins, etc. The main brands of accessories include conductivity meters, PLC programs, dosing pumps, etc. The main difference between the two is that the former plays a decisive role in equipment operation, while the latter plays an auxiliary role in equipment operation, and the relative cost is relatively low.

The brand is mainly divided into two parts, one is the core brand and the other is the accessory brand. The main comparison is as follows

Core brand:

Southern Pump (Domestic High Quality) vs Grundfos Pump (Imported)

Huitong RO membrane (domestic high-quality) vs Dow, Hydergy RO membrane (imported)

EF EDI (domestic high-quality) vs Siemens EDI (imported)

Zhengguang Polishing Resin (Domestic High Quality) VS Dusheng Polishing Resin (Imported)

Accessory brand:

Conductivity meter, pH meter, etc. (domestic high-quality) V American GF conductivity meter, pH meter, etc. (imported)

PLC program (domestic high-quality including Hong Kong and Taiwan) vs Siemens PLC program (imported)

The core brand, whether domestically produced or imported, has high market transparency in terms of price and is basically a product of one penny, without any price perception errors. The imported pump, RO film, EDI, and polishing resin of the same specifications are 2.5 times, 1.5 times, 2 times, and 2 times higher than those of domestic high-quality brands, respectively.

Some Chinese people have low awareness and low demand for accessory brands, but once selected, the cost proportion also increases significantly. Especially for conductivity meters of small and multi-level equipment, if imported brands are chosen, it will be reflected in case studies later.

In addition to the above variable factors, there is also a part of the equipment composition that is relatively fixed in cost or trivial, which can be summarized as linear parts and auxiliary materials, respectively.

Linear part: mainly includes various filter tanks and precision filters, which are mainly related to equipment specifications and have a clear linear relationship. The cost is relatively easy to calculate, and if there are no special requirements for the material, the possibility of change is unlikely.

Auxiliary materials: various filter fillers (excluding polishing resin), equipment brackets, switches without specified brands, flow meters, dosing boxes, etc. This part of the cost is relatively difficult to estimate, but its proportion is limited and the error is not significant. The brands of auxiliary materials and accessories intersect, and auxiliary materials without designated high priced imported brands, except for conductivity meters and PLC programs, can basically belong to auxiliary materials.

With the above basic concepts in mind, we are conducting some analysis based on actual cost accounting cases and calculation formulas.

We have selected the following common equipment specifications (different processes+different water production rates) and compared them with four different configurations: conventional configuration, individual material optimization, individual core brand optimization, and top configuration.

Equipment process: First level RO pure water, second level RO pure water, second level RO+EDI pure water (purified water and high-purity water configuration), 18M ultra pure water (second level RO+EDI+polishing resin, hereinafter referred to as ultra pure water), respectively referred to as ABCD process.

Equipment water production: 1T/H, 5T/H, 25T/H. The 1T/H equipment serves as the basic reference quantity for easy calculation. For 5T/H equipment, whether it is the selection of membrane shells for large equipment (using multiple membrane shells of 5 is more complex and related to end flow, membrane pressure difference, etc.), at the same time, the first stage RO equipment of 5T/H has many similarities with the second stage RO equipment of 2T/H (the pre-treatment part is almost the same, with the addition of a second stage high-pressure pump and transfer water tank), which can be cross compared. And the 25T/H equipment, especially the 25T/H ultra pure water equipment, has typical characteristics of high flow equipment, which can provide some reference for large equipment demanders.

Configuration combination: conventional configuration (PE water tank, UPVC pipeline, Southern pump, Huitong RO membrane, Aifu EDI and other domestic high-quality), material optimization (using 304 stainless steel), core brand optimization (using Grundfos pump, Dow RO membrane, Siemens EDI, Dusheng polishing resin), top configuration (material stainless steel, imported core, imported accessories), respectively referred to as GXYZ configuration.

There are a total of 48 different processes, water production, and configuration combinations. For the convenience of expression, use the following combination to explain:

AG1:1T/H primary reverse osmosis conventional configuration, with a water production capacity of 1T/H

BG5: Conventional configuration of 5T/H secondary reverse osmosis, with a water production capacity of 5T/H

CX25: 25T/H secondary reverse osmosis+EDI stainless steel configuration, with a water production capacity of 25T/H

DZ25: 25T/H 18M ultra pure water top configuration, with a water production capacity of 25T/H

In the first level RO process state, assuming the specification is water production X (T/H)

Linear part: quartz sand, activated carbon, softener, small (below 30 tons) mainly made of fiberglass, large (above 30 tons) mainly made of carbon steel, precision filter mainly made of stainless steel. This part of the equipment has a clear linear relationship, and the approximate formula is as follows

Fiberglass reinforced quartz sand (including filler): 260X+20X=280X carbon steel quartz sand=1080X

Fiberglass reinforced plastic activated carbon (including filler): 260X+40X=300X Carbon steel activated carbon=1120X

Fiberglass multimedia (including filler): 260X+40X=300X carbon steel multimedia=1120X

Fiberglass softener (including filler): 260X+160X=420X Carbon steel softener=1360X

Precision filters: bag filters (5-200 microns) and PP cotton filter cartridges (0.1-10 microns). Filter bags and filters are both very cheap, and when calculating the cost, they are all included in the auxiliary materials.

Bag filter: One No. 1 bag has a flow rate of 15T/H, and one No. 2 bag has a flow rate of 30T/H. Only PP cotton filter cartridges can be used for low flow rates.

Single bag No.1 bag (ordinary flange) 961.00 yuan

Single bag No.2 bag (ordinary flange) 1156.00 yuan

2 bags (ordinary flange) 4303.00 yuan

3 bags (ordinary flange) 4745.00 yuan

4 bags (ordinary flange) 5925.00 yuan

5 bags (ordinary flange) 6998.00 yuan

6 bags (ordinary flange) 8660.00 yuan

PP cotton filter cartridge filter:

10 inch 3-core (1.5 tons) 280.00 yuan

10 inch 5-core (2.5 tons) 330.00 yuan

20 inch 3-core (3 tons) 340.00 yuan

20 inch 5-core (5 tons) 380.00 yuan

20 inch 7-core (7 tons) 525.00 yuan

30 inch 5-core (7.5 tons) 515.00 yuan

30 inch 7-core (10.5 tons) 600.00 yuan

40 inch 5-core (10 tons) 620.00 yuan

40 inch 7-core (14 tons) 780.00 yuan

40 inch 10 core (20 tons) 1760.00 yuan

40 inch 15 core (30 tons) 2680.00 yuan

40 inch 20 core (40 tons) 3750.00 yuan

40 inch 27 core (50 tons) 3980.00 yuan

40 inch 36 core (60 tons) 4960.00 yuan

40 inch 40 core (80 tons) 5700.00 yuan

40 inch 50 core (100 tons) 6280.00 yuan

Material section: The main materials related to water tanks, pipelines, and membrane shells.

Water tank section: For a single water tank, T represents the actual tonnage of the individual water tank. First level RO equipment, raw water tank T1=2X, transfer water tank T2=2X, pure water tank T3=X.

Note: In the case of high flow rate (20T/H), the raw water tank and transfer water tank can be designed with a flow rate of 1/2 or 1/3, while the pure water tank and terminal water tank are generally equal to the flow rate. If the customer has requirements or the venue allows, the design will be based on the hourly flow rate. Equipment with an inflow of less than 6T/H does not require a transfer water tank.

Linear formula for a single PE water tank: 500T

Linear formula for a single 304SUS water tank: 3000+2500T

Example: AG1PE water tank=500 * 2+500 * 1=1500 yuan

Note: 316LSUS material is nearly 50% more expensive than 304SUS material, and there is also a price difference in whether it is sterile grade under the same level of material, which will not be separately introduced. High end materials and sterile requirements often coexist with high process and brand requirements, and are uniformly classified as top of the line equipment.

Pipeline section: The linear relationship of the pipeline section is discontinuous, such as DN25, DN32... DN300, etc. However, from a certain mathematical logic perspective, the simulated linear relationship is as follows:

UPVC/DN25 pipeline=1.6/m, default first level RO is 100m pipeline=160 yuan, with a slight increase in price as the specification pipeline diameter increases.

304SUS/DN25 pipeline=18 yuan/meter, with a default first level RO of 100 meters pipeline=1800 yuan. The price will slightly increase as the diameter of the specified pipeline increases.

Imported PVDF/DN25 pipes are priced at 20 yuan/meter, usually only used at the end of ultrapure water, with limited usage and no comparative consideration. The market price of PVDF is 150-200 yuan/kg.

Flow rate=cross-sectional area of pipeline * flow velocity.

The cross-sectional area of the pipeline is equal to the square of the inner diameter of the pipeline * 3.14/4.

From the above two equations, it can be seen that under the condition of constant flow velocity, the flow rate is directly proportional to the cross-sectional area of the pipeline, that is, the flow rate is equal to the diameter of the pipeline

Square is proportional. The calculation formula for the weight of 304 stainless steel pipes is based on the density of stainless steel and is calculated through parameters such as pipe length, outer diameter, and wall thickness. Among them, the density of stainless steel is 7.93 g/cm ³, The calculation formula is:

Weight=π * (outer diameter thickness) * wall thickness * length * 7.93

Under the same material, DN32 and DN25, with a thickness of 3mm, have a weight ratio of (outer diameter 1- wall thickness)/(outer diameter 2- wall thickness)=(inner diameter 1+wall thickness)/(inner diameter 2+wall thickness)=35/28, which is approximately equal to inner diameter 1/inner diameter 2. The weight of the pipeline is nearly linearly related to the diameter of the pipeline.

In summary, the flow rate is directly proportional to the square of the pipe diameter, the weight is directly proportional to the pipe diameter, and the flow rate is directly proportional to the square of the weight. When the material weight determines the price. The flow rate (X) is directly proportional to the square of the price, and as the flow rate increases, the price increases in proportion to the root sign X. For example, the price of one ton is 1.6 yuan per meter, and the price of three tons is approximately 2.7 yuan per meter based on the square root of 3 multiplied by 1.6. Similarly, the price of a 25T flow pipeline is 5 * 1.6=8 yuan/meter. So the cost of UPVC pipeline for the first level RO equipment at a flow rate of 25t/h is 8 * 100=800 yuan. The price proportion in the entire equipment system is very low, and the price of UPVC material pipes can be ignored. If it is made of 304SUS material (AX25 equipment), the cost is 18 * 5 * 100=9000 yuan. Although the cost proportion is still limited, it has reached a level that cannot be simply ignored.

The default first level RO is a 100 meter pipeline, second level RO is 200 meters, second level+EDI is 250 meters, and 18M ultra pure water is 300 meters long.

The cost formula for the first level RO equipment pipeline is as follows:

UPVC=160 * X ^ (1/2)

304SUS=1800 * X ^ (1/2)

Membrane shell part: The membrane shell of RO equipment generally has R8040-N (1-7), which is often configured as an integer multiple, or the total capacity of the membrane shell is slightly larger than the actual total number of membranes. Medium size equipment (20-100 membranes) generally uses 8040-5 membrane shells, with a harmonious proportion of equipment and convenient calculation.

The price of a single membrane shell is as follows:

The prices for fiberglass 8040-1 to 8040-7 are 1600194022702610294532803620, respectively

The prices for 304 stainless steel 8040-1 to 8040-6 are 2340322041004498058606730, respectively

The number of membrane shells=X/model N, taken as an integer.

For example, for 12 membranes, choose 3 8040-4 membrane shells. Why not choose 4 8040-3 membrane shells?

Select 3 membrane shells, which can form a 2:1 two-stage combination (refer to the previous text for multi-level and multi-stage combinations), and select 6 8040-5 membrane shells for 30 membranes. Using 4; The combination method of 2. In theory, the fewer membrane shells there are, the lower the cost (5 8040-6 are cheaper than 6 8040-5), but the combination method is more important.

Linear formula for membrane shell

Single fiberglass: 1260+340X

Multiple fiberglass tubes: 1260+340X+1260 * ⌊ X/N-1 ⌋ (rounded up, the same below), N is the membrane shell specification

Single 304SUS: 1460+880X

Multiple 304SUS: 1460+880X+1460 ⌊ X/N-1 ⌋, N is the membrane housing specification

The formula for multiple membrane shells is applicable to a single membrane shell, so the formula can be unified into the formula for multiple membrane shells.

Note: For equipment with a water production rate of 3T/H or less, 4040 membranes are commonly used (with a water production rate equivalent to 1/4 of 8040 membranes, 0.25-0.3T/H water production rate). Compared to 1-2 8040 membranes, multiple 4040 membranes can be better combined into a multi-stage combination, increasing the proportion of pure water preparation (from 50% to about 75%). At the same time, the distribution and size of the equipment will also be more reasonable and aesthetically pleasing. Under the same brand status, the price of four 4040RO membranes with membrane shells is slightly higher than that of one 8040RO membrane with membrane shell, which is about 25% -30% more expensive.

Brand section: Core brand+accessory brand

Core brands: pump, RO film, EDI, polishing resin

Pump: The model of the pump is generally selected based on the supplier's parameters, and the linear relationship is not obvious and complex. Calculate the formula based on experience. The pump is divided into high-pressure pump and delivery pump.

First stage RO: 2 conveying pump+1 high-pressure pump

Secondary RO: 2 conveying pump+2 high-pressure pump

Secondary RO+EDI: 3 conveying pump+2 high-pressure pump

Secondary RO+EDI+polishing: 4 conveying pumps+2 high-pressure pumps

RO membrane: 8040 membrane simple linear relationship

Huitong 8040:2400X

Dow 4040:3600X

EDI device: EF VS Siemens

EF: 9000+4500X

Siemens: 15000+8000X

Polishing resin: Domestic VS Dusheng

Domestic resin: 750X

Du Sheng resin: 1580X

The formula is as follows:

Domestic: 35-45 yuan/L

Du Sheng: 85 yuan/L

Flow X= Π R ^ 2 * flow rate (taken as 18m/H), filling volume= Π R ^ 2 * 2/3h (tank height)

Polishing resin tanks often use 1054/1254 tanks, and when the flow rate is insufficient, parallel connections are used to increase the flow rate. The tank height of 1450mm is uniform. At flow rate X, the filling volume is 18.6L. The market generally believes that the processing capacity of 1L polishing resin ultra pure water is 60-70L, which is consistent with the calculation results.

Accessory brand: Domestic high-quality VS American GF

The usage of accessory equipment is relatively fixed

Conductivity meter: number of sets=number of stages (number of core devices).

PLC program: 1 set, domestic 2500, Siemens 5000-10000.

PH meter: Several quantities (average unit price, not calculated separately).

Domestic conductivity meter: 3000 per set

GF conductivity meter: 6500 per set

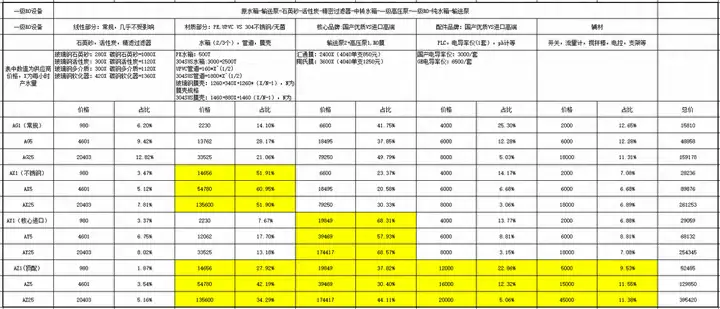

Comparison of prices for different configurations of primary RO equipment:

The marked part is the high-end part

We found several simple conclusions through the table

1: Material optimization has a significant impact on equipment costs

In the top configuration, the cost proportion of material optimization has increased from 21.11% (average cost proportion of conventional configuration, the same below) to 34.80%, with an increase of 64.9%. At the same time, the proportion of other components has been squeezed to varying degrees. In the case of only selecting material optimization, choosing stainless steel increased the cost proportion from 21.11% to 54.91%, which is a very exaggerated proportion. Almost the entire equipment is paying for a few water tanks.

Reflected in real life, it can be found that under the same equipment specifications, the price of pure water equipment required by medical and food industries will increase significantly! If a 316L sterile water tank is used and sanitary grade stainless steel pipes are used, the equipment cost can reach 3.5 times the conventional configuration, or even higher. In non essential situations, it is not necessary to choose stainless steel material, which will significantly increase equipment costs and procurement prices.

2: Is optimizing the core (equipment) brand worth choosing?

In the top configuration scenario, the cost of high-end core brands accounts for 37.44%, which is slightly lower than the cost of conventional (domestic high-quality) brands at 43.12% in conventional configurations, mainly due to material optimization.

In the case of only selecting high-end core equipment, the cost proportion increased significantly from 43.12% to 64.93%. However, considering that almost half of the cost of this configuration is consumables, it can be compensated for in terms of replacement cycle, cost, stability, and other aspects in the later stage. Considering that the increase in comprehensive system costs caused by pumps and consumables is 19.8% and 10.3% respectively (this data cannot be reflected in the table). If budget conditions permit, I personally recommend using imported RO film, and if conditions permit, using imported EDI and polishing resin, and adopting a wait-and-see attitude towards pump selection.

Note: The table is a supplier purchase price data table, and some of the data cannot be derived from the simple formula above.

According to the relevant formulas of the primary RO equipment, the formula for the relationship between the secondary RO equipment and the water production X is derived as follows.

Linear part: Filter, small (below 30 tons) mainly made of fiberglass, large (above 30 tons) mainly made of carbon steel, precision filter mainly made of stainless steel.

Fiberglass reinforced quartz sand (including filler): 390X+30X=420X Carbon steel quartz sand=1620X

Fiberglass reinforced plastic activated carbon (including filler): 390X+60X=450X Carbon steel activated carbon=1680X

Fiberglass multimedia (including filler): 390X+60X=450X, carbon steel multimedia=1680X

Fiberglass softener (including filler): 390X+240X=630X Carbon steel softener=2040X

Water tank section: For a single water tank, T represents the actual tonnage of the individual water tank. Secondary RO equipment, raw water tank T1=2X, transfer water tank T2=2X, pure water tank T3=1.5X, T4=X.

Note: In the case of high flow rate (20T/H), the raw water tank and transfer water tank can be designed with a flow rate of 1/2 or 1/3, while the pure water tank and terminal water tank are generally equal to the flow rate. If the customer has requirements or the venue allows, the design will be based on the hourly flow rate. Equipment with an inflow of less than 6T/H does not require a transfer water tank.

Linear formula for a single PE water tank: 500T

Linear formula for a single 304SUS water tank: 3000+2500T

For example, BG1PE water tank=500 * 2+500 * 1.5+500 * 1=2250 yuan.

Pipeline section: default to first level RO equipment, with a pipeline length of 100 meters, and second level RO equipment with a pipeline length of 200 meters. The water inflow of secondary equipment under the same specifications is 1.5 times that of primary equipment.

The linear formula for obtaining the pipeline of the secondary RO equipment is as follows:

UPVC pipeline=320 * 1.22 * X ^ (1/2)=390 * X ^ (1/2)

304SUS pipeline=3600 * 1.22 * X ^ (1/2)=4390 * X ^ (1/2)

Membrane shell part: The membrane shell of the secondary RO equipment is divided into the front section and the rear section. The front section is equal to 1.5X membrane shell distribution, and the membrane shell distribution at the back end is the same as that of the same level RO equipment.

Fiberglass membrane shell: 1260+340 * 1.5X+1260 * ⌊ 1.5X/N-1 ⌋+1260+340X+1260 * \8970X/N-1 ⌋

=2520+850X+1260 * (⌊ 1.5X/N-1 ⌋+\8970X/N-1 ⌋), N is the membrane shell specification

304SUS membrane housing: 1460+880 * 1.5X+1460 ⌊ 1.5X/N-1 ⌋+1460+880X+1460 ⌊ X/N-1 ⌋

=2920+2200X+1460 * (⌊ 1.5X/N-1 ⌋+\8970X/N-1 ⌋), N is the membrane shell specification

Core brand part: RO membrane

Huitong membrane: 2400 (X+⌊ 1.5X ⌋)

Dow membrane: 3600 (X+⌊ 1.5X ⌋)

专业水处理的疑难问题,产品选型问题,可以单击下面的微信二维码电话联系贺工在线指导,长按微信二维码可自动识别添加贺工微信沟通解决您的疑难问题

简体中文

简体中文 Vietnamese

Vietnamese Persian

Persian 繁体中文

繁体中文 Albanian

Albanian Irish

Irish Arabic

Arabic