The electronic industry (such as semiconductor devices, integrated circuits, picture tubes, etc.) extensively uses various levels of pure and high-purity water to clean semi-finished and finished products. The quality, qualification rate, and reliability of products in the microelectronics industry (semiconductor devices, integrated circuits, CRT electronic detection, computer motherboards, etc.) are closely related to the water quality of pure or high-purity water.

With the development of the electronics industry, especially the rapid growth of the semiconductor industry, the requirements for pure water quality are constantly increasing. Previously, the practice of using electrical resistivity as the only measure of water quality purity was far from enough after practical testing. Gradually, quantitative indicators and limitations have been established for the anion content, cation content, particle number, organic matter, bacteria, etc. in water.

In the mid-1970s, the determination of five indicators, namely particles, bacteria, silica, sodium, and total organic carbon, ensured the quality of integrated circuits. In the 1980s, due to the further improvement of integration, the requirements for pure water quality, especially for particles and bacteria, were more stringent. On this basis, the limit index of dissolved oxygen was added. Because the concentration of dissolved oxygen was too high, the gas released during the silicon wafer cleaning process would not only produce foam and make the wafer surface unable to be completely cleaned, but also the dissolved oxygen in hot ultra pure water would corrode the integrated circuit wafer.

In the 1990s, integrated circuits had developed to the megabit level of submicron technology, and the processing and cleaning of chips had stricter requirements for the quality of pure water. In order to ensure production needs, each major pure water treatment company has its own set of process systems to adapt to the needs of different integration levels of production. Although not completely identical, they basically use reverse osmosis, ion exchange, ultrafiltration, and other membrane separation technologies to form a series of corresponding standard processes. The development of China's microelectronics industry is relatively slow, and the technology for preparing ultrapure water is also far behind that of developed countries in the world. In the integrated circuit production plants that have been built, all pure water preparations are made using imported equipment from abroad.

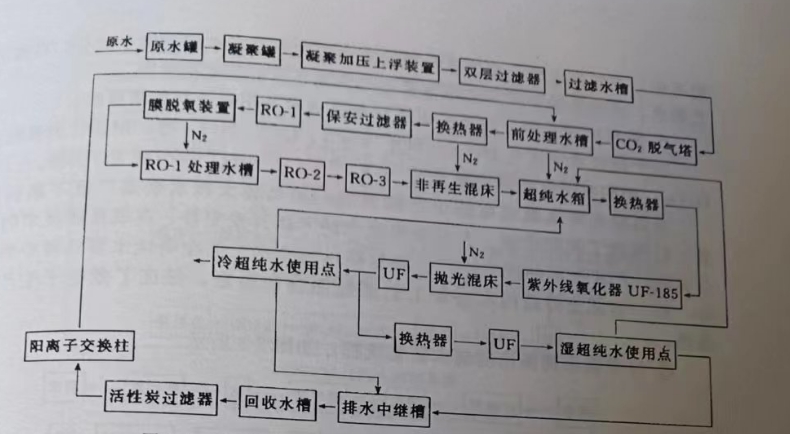

The pure water preparation process designed by Jiajie Pure Water in a large-scale integrated circuit production plant in Shanghai is shown in the following figure. The system consists of pre-treatment system, primary pure water manufacturing system, secondary pure water manufacturing system, water recovery and other supporting systems.

专业水处理的疑难问题,产品选型问题,可以单击下面的微信二维码电话联系贺工在线指导,长按微信二维码可自动识别添加贺工微信沟通解决您的疑难问题

简体中文

简体中文 Vietnamese

Vietnamese Persian

Persian 繁体中文

繁体中文 Albanian

Albanian Irish

Irish Arabic

Arabic